ADHESIVE LITHIUM GREASE

MULTI-SERVICE MULTI-PURPOSE

EXTREME PRESSURE, ANTI-WEAR, ANTI-CORROSION

EXCELLENT STABILITY IN DAMP ENVIRONMENTS

GENERAL LUBRICATION FOR USE IN MECHANICAL AND MAINTENANCE ENVIRONMENTS

DESCRIPTION

Ultra high performance multi-purpose complex lithium grease. Polymer-based multi-purpose grease, for long-term lubrication. In aerosol form for all those difficult-to-access or moving mechanical components with a complex geometry requiring maximum penetration.

Adhesive, resistant to centrifugation.

High level of resistance to the effects of shearing and to vibrations.

Excellent stability in damp environments, and in humidity, water, steam and saline environments.

FIELDS OF APPLICATION

Rigid bearings, ball bearings, roller bearings, needle roller bearings, toroidal bearings.

Cam rollers, with axle, roller brackets.

Bearings, open reducers, gears, cogwheels, toothed wheels, racks.

Cardan joints.

Ball joints, hinges, split hinges.

Linear guidance systems, including ball bearing circulation, under heavy loads.

Use as an aerosol spray for lubrication during operation on open mechanical components.

INSTRUCTIONS FOR USE

Shake the aerosol can vertically for a few moments after the ball in the can becomes detached.

First degrease the mechanism to be lubricated and apply Neutralène® V200 aerosol if needed. www.degraissantrapide.com

Spray at a distance of 15 to 25 cm depending on the size of the mechanism.

PHYSICO-CHEMICAL PROPERTIES TYPICALS

|

PHYSICAL PROPERTIES OF THE GREASE |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Appearance |

visual |

smooth, viscous |

nm |

|

Colour |

in |

amber |

nm |

|

Apparent density at 25°C/77°F (pycnometer) |

NF T 30 020 |

877 |

kg/m³ |

|

NLGI Class |

NLGI National Lubricating Grease Institute |

2 |

Classification |

|

Thickener |

- |

Lithium |

- |

|

solid lubricant content |

- |

Without |

% |

|

Penetrability at 25°C/77°F Non-worked Worked, 60 strokes Worked, 1,000 strokes Worked, 10,000 strokes Worked, 100,000 strokes |

NF ISO 2137 / ASTM 2176

|

265-295 265-295 265-295 275-305 280-310 |

1/10° mm 1/10° mm 1/10° mm 1/10° mm 1/10° mm |

|

Dropping point Dropping point if greater than 360°C/680°F |

NF ISO 2176 /ASTM D 566 ASTM D 2265 |

187°C/368,6°F

|

-

|

|

Impurities > 25 µm > 75 µm > 125 µm |

FMTS 791 3005 |

0 0 0 |

nb/ml |

|

PHYSICO-CHEMICAL PROPERTIES OF THE BASE OIL |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Type of base oil |

- |

Mineral |

- |

|

Kinematic viscosity at 40°C/104°F Kinematic viscosity at 100°C/212°F |

NF EN ISO 3104 |

140 110 |

mm2/s mm2/s |

|

Acid value (AV) |

NF ISO 6618 |

0.4 |

mg KOH/l |

|

PERFORMANCE PROPERTIES |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Oil separation, 7 days at 40°C/104°F (bleeding) |

NF T 60 191 |

0 |

% of mass |

|

Oil separation 24 hours at 41 kPa (bleeding under pressure) |

ASTM D 1742 |

5 |

% of mass |

|

Sulphated ashes |

NF T 60 144 |

1.2 |

% of mass |

|

Copper strip corrosion |

ASTM D 4048 |

1b |

Rating |

|

Hoffman oxidation |

ASTM D 942 |

<50 |

psi |

|

Loss by evaporation 22 hours at 121°C/249,8°F |

ASTM D 972 |

0.2 |

% of mass |

|

Noack evaporation loss |

NF T 60 101 CEC L-40 A-93 ASTM D5800 |

< 1 |

% of mass

|

|

Elastomer swelling 70h at 100°C/212°F |

ASTM D 4289.83 |

0.4 |

Dimensional variation % |

|

Temperature ranges Continuous Peak |

- - |

-20°C +170°C/-4°F +338 °F -20°C +180°C/-4°F +356°F |

- |

|

Rotation factor |

n.dm |

500,000 |

mm/min-1 |

|

4-ball test Wear scar diameter Wear load index |

ASTM D 2266 / ISO 20 623

|

0.8 2500 |

mm N |

|

TIMKEN Test |

ASTM D 2509 |

30 |

lbs |

|

EMCOR rust prevention test Dynamic Static |

NF T 60 135 ISO DP 6294/ ASTM D 1743 |

1 1.8 |

Rating Rating |

|

Resistance to water washout at 80°C/176°F |

ASTM 1264 |

6 |

% of mass |

* not measured or non-measurable

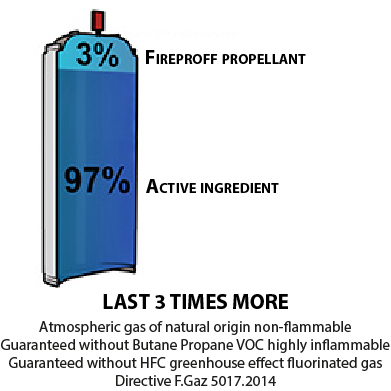

PRESENTATIONS

|

|

Aerosol 650 ml

|

Tin 1L  |

Cartridge 430ml  |

Looking for another product?

|

Discover our entire range by clicking on the photo |

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.

.jpg)